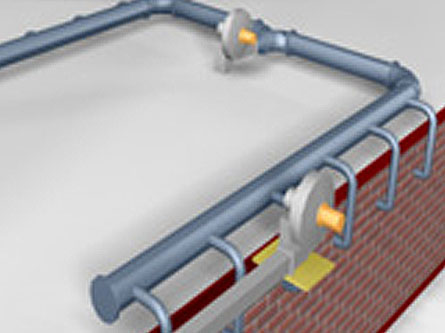

Recirculators

Recirculators work by extracting fumes from the lower section of the wagon by means of lateral capillaries and a centrifugal fan. The gas volume is injected via pipes spread across de kiln upstream from extraction area.

The fan’s effect is twofold: First it provides kiln gas extraction where the draw is lowest, i.e. at the lower section of the package, helping to enhance pre-heating in this area of the package as there are more circulating fumes; Secondly, air injection in the upper section of the kiln produces a curtain and a loss of load, generating turbulence in the other fumes coming from the firing area, sucked by the draw.

This dual action achieves greater and better heat exchange between fumes and material, enhancing heating of material in the area and more consistent temperatures between the upper and lower sections of the package.