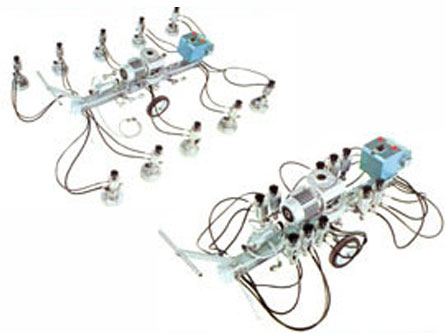

BIC/10 pulse burners

This model in the Beralmar burner line-up is the result of research into new ceramics firing techniques in moving kilns (Hoffman, Zigzag, Chambers, etc..) and fixed kilns (Tunnel).

The main feature of this Unit is significant is that it does away with the pump and instead uses an independent injection unit (one for each burner nozzle), which in operation reaches a injection pressure of 100 kg/cm2, at 30 to 46 pulses per minute.

Its operation could not be easier, ensuring consistent fuel spray inside the kiln. Continuous circulation of heavy diesel, combined with internal pre-heating of the Unit, ensures that the equipment will work properly, even when the ambient temperature is very low.

In addition it allows for accurate regulation pressure and diesel quantity at each nozzle. The entire Unit is fitted to a frame with rubber castors to facilitate manoeuvring and transport over the kiln hood, essentially comprising a pumping unit, with reducer motor, diesel pre-heating tank (fitted to the frame), injector unit (one for each nozzle) and control panel.

GCI burner units are capable of supplying 6-8-9-10 nozzles in two rows each.