News

New project for a complete plant in Kazakhstan (Dec 22, 2017)

BERALMAR is working to supply a new production line for the BOSHAN ceramics plant situated a few kilometres from Astana, the capital of Kazakhstan.

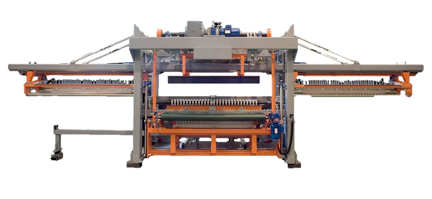

BOSHAN’s order includes a LLEVANT model direct-load dryer on a kiln car and a PRESTHERMIC model airtight tunnel kiln. The three tunnels (two for drying and one for firing) are designed with the following dimensions: 106 m in length, a useful width of 4.70 m and a useful height of only 1.54 m, which is a moderate height as fits direct-load kiln-car facilities. Nominal production is 30 million NF/year of various solid, hollow and thermoclay formats.

Production lines with dryers directly loading green material onto kiln cars are not always a technically viable option as they depend on the suitability of the clay available and the formats to be manufactured, but when they are viable, as in this case, they have numerous advantages, especially the following:

Also noteworthy in this project is the multiple cutter with four-sided bevelling. The versatility of the dryers with direct kiln-car stacking enables the new factory to be a multi-product factory, and some formats will be bevelled.

BERALMAR happens to have accumulated very positive experience in supplying both direct kiln-car stacking lines and solid-fuel consumption equipment for drying and firing processes and these are surely reasons involved in BERALMAR being chosen for this project.

This is the second order BERALMAR has received from the central Asian country, following the order for a PROMATIC facility, which we referred to through this medium recently.

+ info:

BOSHAN’s order includes a LLEVANT model direct-load dryer on a kiln car and a PRESTHERMIC model airtight tunnel kiln. The three tunnels (two for drying and one for firing) are designed with the following dimensions: 106 m in length, a useful width of 4.70 m and a useful height of only 1.54 m, which is a moderate height as fits direct-load kiln-car facilities. Nominal production is 30 million NF/year of various solid, hollow and thermoclay formats.

Production lines with dryers directly loading green material onto kiln cars are not always a technically viable option as they depend on the suitability of the clay available and the formats to be manufactured, but when they are viable, as in this case, they have numerous advantages, especially the following:

- Low energy consumption: the combined energy consumption anticipated between the drying and firing is 330 kcal/kg.

- Low presence of automation systems, and the other advantages that this entails: lower investment in machinery, less maintenance and fewer production stoppages.

Also noteworthy in this project is the multiple cutter with four-sided bevelling. The versatility of the dryers with direct kiln-car stacking enables the new factory to be a multi-product factory, and some formats will be bevelled.

BERALMAR happens to have accumulated very positive experience in supplying both direct kiln-car stacking lines and solid-fuel consumption equipment for drying and firing processes and these are surely reasons involved in BERALMAR being chosen for this project.

This is the second order BERALMAR has received from the central Asian country, following the order for a PROMATIC facility, which we referred to through this medium recently.

+ info: