Meldungen

Modernisation of the SAVERDUN TERRE CUITE CERAMICS facility (01.10.2009)

BERALMAR has carried out an important modernisation project at the SAVERDUN TERRE CUITE ceramics facility in Saverdun (France). SAVERDUN TERRE CUITE is a manufacturer of over one hundred formats and specialises in high quality ceramic finishes.

The projects objectives were 1) to increase production, 2) to optimise quality and 3) to automate the manufacturing processes.

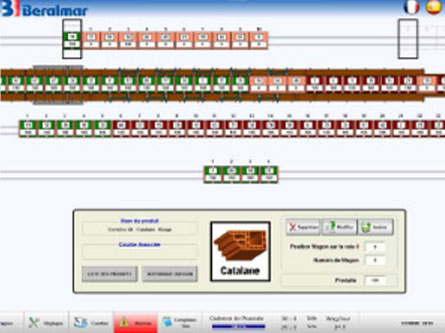

To achieve these onjectives, new gas combustion equipment and kiln ventilation were installed. A new air recovery system for the dryer with a mixing chamber and gas burner was also installed. But the most interesting changes were the installation of a new automatic control system for the kiln and dryer and the new transport system with "car tracking" for the automated tracking of each wagon and management of the firing curve depending on the load, which is a very important aspect considering the endless list of formats manufactured in this facility.

It should be noted that the automatic kiln management control system incorporates an alarm and incident management system which allows the total absence of personnel in the facility over the whole weekend, with the help of a warning system using text messages and e-mails.

+ info:

The projects objectives were 1) to increase production, 2) to optimise quality and 3) to automate the manufacturing processes.

To achieve these onjectives, new gas combustion equipment and kiln ventilation were installed. A new air recovery system for the dryer with a mixing chamber and gas burner was also installed. But the most interesting changes were the installation of a new automatic control system for the kiln and dryer and the new transport system with "car tracking" for the automated tracking of each wagon and management of the firing curve depending on the load, which is a very important aspect considering the endless list of formats manufactured in this facility.

It should be noted that the automatic kiln management control system incorporates an alarm and incident management system which allows the total absence of personnel in the facility over the whole weekend, with the help of a warning system using text messages and e-mails.

+ info: