Meldungen

Modernization in the drying and firing process for BRAMPTON BRICK (25.04.2023)

BRAMPTON BRICK, one of the leading brick manufacturing companies in Canada, has relied on the experience and know-how of BERALMAR TECNOLOGIC S.A to carry out a significant modernization in one of its plants.

The modernization project has required the installation of:

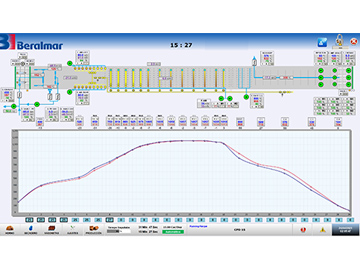

In addition, the MICROSEC Control for the dryer and the MICROBER Control for the tunnel kiln have been implemented, allowing for continuous monitoring and control of the production process and improving the quality of the final product.

This modernization has allowed for an improvement in their production process, offering higher quality products, and meeting the high-quality standards demanded by the market.

In this regard, the equipment supplied by Beralmar Tecnologic is already operating successfully, allowing Brampton Brick to improve its production capacity and meet the demands of its customers.

From Beralmar Tecnologic, we would like to thank Brampton Brick for their trust in us and for allowing us to carry out such a significant project.

Our commitment to the ceramic industry is to continue developing innovative and efficient solutions to improve the quality and efficiency of brick and other ceramic material production

The modernization project has required the installation of:

- 18 self-ignition high-speed gas burners of the FOC20/ML model.

- 5 groups of self-ignition high-speed gas burners of the FOC20/MV model.

- 8 impulse gas burners of the ICV model.

- 1 air vein of 1,000,000 Kcal/h of the VA-10 model.

In addition, the MICROSEC Control for the dryer and the MICROBER Control for the tunnel kiln have been implemented, allowing for continuous monitoring and control of the production process and improving the quality of the final product.

This modernization has allowed for an improvement in their production process, offering higher quality products, and meeting the high-quality standards demanded by the market.

In this regard, the equipment supplied by Beralmar Tecnologic is already operating successfully, allowing Brampton Brick to improve its production capacity and meet the demands of its customers.

From Beralmar Tecnologic, we would like to thank Brampton Brick for their trust in us and for allowing us to carry out such a significant project.

Our commitment to the ceramic industry is to continue developing innovative and efficient solutions to improve the quality and efficiency of brick and other ceramic material production