Meldungen

Order of firing equipment for synthesis gas (29.10.2020)

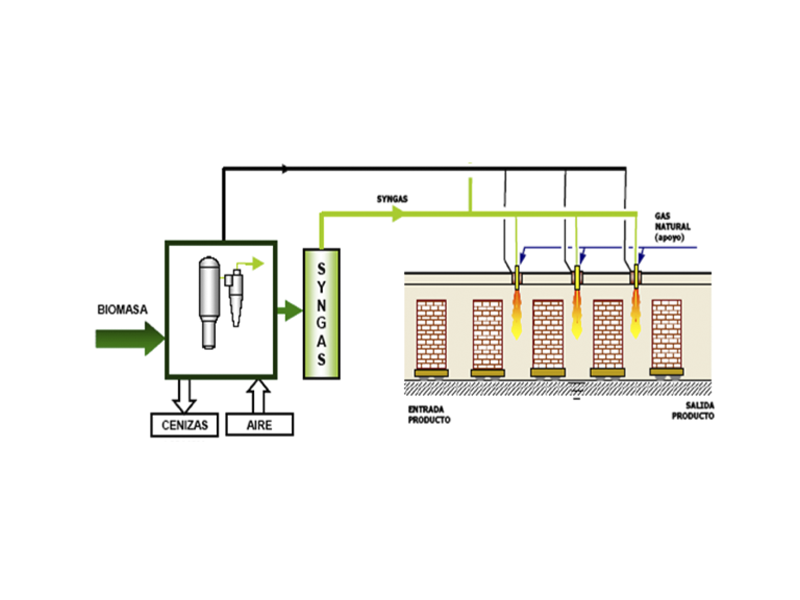

BERALMAR is working on a very significant order: the supply of dual firing equipment that can work with both natural gas and synthesis gas.

The project includes a modular gasification system supplied by NAODEN, a French manufacturer specialized in these technologies.

The equipment is destined for a BOUYER LEROUX group factory in north-western France, which has made a courageous commitment to this technology when facing the challenge posed by the imperative need to significantly reduce the volume of CO2 emissions.

Synthesis gas, also known as syngas, is a gas obtained from the anaerobic combustion of organic waste (biomass in this case) in a pyro-gasification reactor. Despite its low caloric intake, of just over 1,000 kcal/m3, it can be used perfectly with high-speed burners for the preheating zone, such as those developed by BERALMAR for this project.

All the burners are dual so that it is possible to change fuel and switch to consuming natural gas from the network in case the gasification reactor needs to be stopped for maintenance.

The syngas obtained from biomass is an energy source that computes as neutral when calculating CO2 emissions, so this bet by BOUYER LEROUX is one of the ways in the right direction to replace the consumption of fossil fuels with renewable energy sources, despite not being the only one. BERALMAR has different solutions to reduce CO2 emissions both in the firing and drying processes.

This new BOUYER LEROUX firing facility will be commissioned in spring 2021.

+ info:

The project includes a modular gasification system supplied by NAODEN, a French manufacturer specialized in these technologies.

The equipment is destined for a BOUYER LEROUX group factory in north-western France, which has made a courageous commitment to this technology when facing the challenge posed by the imperative need to significantly reduce the volume of CO2 emissions.

Synthesis gas, also known as syngas, is a gas obtained from the anaerobic combustion of organic waste (biomass in this case) in a pyro-gasification reactor. Despite its low caloric intake, of just over 1,000 kcal/m3, it can be used perfectly with high-speed burners for the preheating zone, such as those developed by BERALMAR for this project.

All the burners are dual so that it is possible to change fuel and switch to consuming natural gas from the network in case the gasification reactor needs to be stopped for maintenance.

The syngas obtained from biomass is an energy source that computes as neutral when calculating CO2 emissions, so this bet by BOUYER LEROUX is one of the ways in the right direction to replace the consumption of fossil fuels with renewable energy sources, despite not being the only one. BERALMAR has different solutions to reduce CO2 emissions both in the firing and drying processes.

This new BOUYER LEROUX firing facility will be commissioned in spring 2021.

+ info: