Notícias

Process improvements for the NEXE group (28/06/2019)

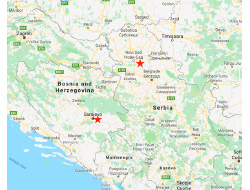

BERALMAR has recently carried out improvement projects in two factories of the NEXE group. With a total of 11 tunnel kilns distributed around Croatia, Serbia and Bosnia, for the manufacture of blocks and tiles, the NEXE group is the most important manufacturer in the Balkan region and a customer to whom BERALMAR has supplied different combustion solutions.

In recent months BERALMAR has successfully carried out the following production improvements at the TOS (Sarajevo, Bosnia) and IGM STRAŽILOVO (Sremski Karlovci, Serbia) factories:

TOS (Bosnia)

Modification and equipping of the kiln to achieve:

IGM STRAŽILOVO (Serbia)

Modification of the dryer of the old line, dividing the control of the drying process into zones and improving ventilation, with the following objectives:

Both projects were carried out cost-effectively and fully achieved the objectives.

They say, with good reason, that it is easier to build a new facility than to make improvements or troubleshoot an existing one. The above interventions carried out in these NEXE group plants once again highlight one of BERALMAR’s traditional strong points: the ability to improve processes in existing plants. An ability which the markets in which BERALMAR has traditionally operated are very aware of, but which is now slowly becoming known in many other parts of the world, as on this occasion in the Balkans.

+ info:

In recent months BERALMAR has successfully carried out the following production improvements at the TOS (Sarajevo, Bosnia) and IGM STRAŽILOVO (Sremski Karlovci, Serbia) factories:

TOS (Bosnia)

Modification and equipping of the kiln to achieve:

- An increase in kiln production to 400 tonnes/day.

- An increase in quality (decrease in rejection).

IGM STRAŽILOVO (Serbia)

Modification of the dryer of the old line, dividing the control of the drying process into zones and improving ventilation, with the following objectives:

- An increase in dryer production to 280tonnes/day.

- An increase in drying quality.

Both projects were carried out cost-effectively and fully achieved the objectives.

They say, with good reason, that it is easier to build a new facility than to make improvements or troubleshoot an existing one. The above interventions carried out in these NEXE group plants once again highlight one of BERALMAR’s traditional strong points: the ability to improve processes in existing plants. An ability which the markets in which BERALMAR has traditionally operated are very aware of, but which is now slowly becoming known in many other parts of the world, as on this occasion in the Balkans.

+ info: