|

Approximate reading time: 5 minutes

Ceramics Industry

CONSTRUMATICA MAGAZINE CREATES CONSTRUPEDIA

Inspired by Wikipedia, whose content is provided by its own users, the DE.CONSTRUMATICA magazine has created a similar concept for the construction industry: the CONSTRUPEDIA encyclopaedia.

Inspired by Wikipedia, whose content is provided by its own users, the DE.CONSTRUMATICA magazine has created a similar concept for the construction industry: the CONSTRUPEDIA encyclopaedia.

CONSTRUPEDIA content is growing all the time, currently with 2,935 articles, under categories such as Construction Dictionary, Standards, Measurements, Occupational Risks, Construction Pathologies, Structural Calculations, etc.

Time and, above all, users will tell whether CONSTRUPEDIA will become a good source of all kinds of information linked to construction, but first we must applaud this initiative and wish it well.

|

Corporate

POLISH CERAMIST CONVENTION

The annual Polish ceramist convention took place in Warsaw on 15 and 16 May, where Beralmar gave a presentation on the most energy efficient complete factory model for Poland, using available fuels and the largest number of manufactured pieces.

This hypothetical factory would have a green loading dryer on a kiln wagon, heated only by hot air recovered from the kiln, with a combined gas and mineral coal firing facility.

BERALMAR has achieved great success with this kind of factory, with specific consumption rates of less than 300 Kcal/kg. This efficiency, combined with predominant use of mineral coal, will provide very low operating costs, which particularly during critical market periods are most welcome.

From these pages we should like to thank the Association of Polish Ceramists.

|

|

BERALMAR PRESENTATION IN SERBIA

On 12 June, BERALMAR will be giving a presentation on solid-fuel firing at the 5th Ceramics Industry Convention in Serbia, organised by the Serbian Association of Ceramists (IGP).

BERALMAR’s presentation will discuss technologies that have enabled modern usage of solid fuels in the ceramics industry of many countries, and potential problems involved in using these fuels and how to avoid them.

Bearing in mind that BERALMAR is the only supplier with wide experience in solid fuels, we hope the presentation will be of interest to the attendees.

|

|

BERALMAR PERSONNEL VISIT THEIR OWN CREATIONS

On 9 and 10 May, BERALMAR organised an outing for all company personnel to visit some of their own creations.

The outing was particularly aimed at all company people who, because of the nature of their job, do not have any chance to see the result of their work.

Specifically, three ceramics works were visited: CERÁMICAS DE MIRA (Mira, Cuenca), CERÁMICAS VIDAL-BENEYTO (Turis, Valencia) and CERÁMICAS ALONSO (Ayelo de Rugat, Valencia). Our group was extremely well looked after by these ceramists, and we should like to take this opportunity to thank them for their hospitality.

This was also a wonderful opportunity to share good times, in a situation that necessarily was more relaxed than in the office setting.

|

News and Features

NEW SOLID-FUEL FIRING FACILITY UNDERWAY IN POLAND

In our April newsletter we reported that we had commissioned a Promatic mineral-coal-fired facility in Poland. This time, we can report that we have commissioned a further similar facility at a ceramics works near the town of Bydgoszcz.

This facility supplies 100% of the kiln’s energy requirement, and once again, Polish coal is proving to be an excellent fuel for the ceramics industry. Even though BERALMAR always recommends maintaining gas or fuel-oil fired preheating, in this case moderate production and quality of mineral coal make it possible to rely solely on coal.

Poland has a long tradition of using coal for ceramics kilns, which nowadays is a valid alternative – with the right technology – to the crippling cost of natural gas and fuel oil.

|

|

NEW CERAMICS WORKS COMMISSIONED IN MEXICO

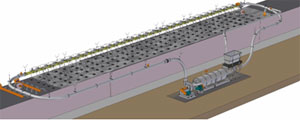

BERALMAR has just commissioned a new ceramics works for LADRILLERA SANTA CLARA, in the border town of Monterrey (Nuevo León, Mexico), which joins the existing face-brick production line.

The dryer is of the semi-continuous type with shelves and the kiln is a sealed PRESTHERMIC, almost 185 metres long with the pre-kiln. The kiln is fitted with gas burners for preheating, and a PROMATIC petroleum coke firing facility, able to produce at least 660 tonnes/day of vaults, hollow bricks (barroblock) and truss channels, locally known as cazuelas. The entire production will be exported to the US. Both dryer and kiln are managed automatically by BERALMAR’s MICROSEC and MICROBER systems.

This is the second factory that BERALMAR has commissioned in Mexico, following construction of a production line for NOVACERAMIC in Tlaxcala.

|

|

|

|