In this issue:

In early October a group of American brickmakers, representing around 75% of the U.S. brick industry, has visited the south of Spain with the objective of gathering an overview of the local industry and technologies.

One of the most remarkable aspects for the visitors was realising the high presence of solid fuels, petcoke to be exact, in the firing of ceramic products, specially taking into account that most petcoke consumed in Spanish brickyards has its origin in the United States.

The energy expense is a matter of growing concern for American brickmakers. The quality of firing using petcoke with BERALMAR’s solid fuel firing systems was an eye opener.

BERALMAR thanks the American brick industry for their visit, hoping it has been fruitful to learn more about the use of this alternative fuel.

Tecnargilla 2006 has come to an end. From this year’s edition, BERALMAR draws two main conclusions:

First of all, given the poor number of visitors compared to previous editions, it is proven that to celebrate the two main exhibitions of the ceramic industry, Ceramitech and Tecnargilla, at the same year is basically a bad idea. With the new frequency of Tecnargilla (2 years), this situation will repeat itself in 2012. Let’s wish a solution will be met on time.

Secondly, the growing interest of the visitors for solid fuel firing systems is a reality. The increasing energy expense brings about some unsustainable situations that call for alternatives, even in countries with a long tradition of firing with natural gas. BERALMAR has developed solid fuel firing systems since 1984, offering an unparalleled experience: more than 100 installations worldwide. BERALMAR continues researching in order to optimise all aspects concerning solid fuels firing.

This fall BERALMAR’s Projects Department has reached the number of 25 engineering projects (kilns, dryers or complete plants) successfully delivered, with a high level of customer satisfaction.

BERALMAR’s Projects Department was created in the late 90’s as an important strategic bet, which, from the current perspective, proves itself right.

Despite the need to fight against the market’s general perception of BERALMAR as a plain supplier of equipment, the Department ran since day one by Artur Massaguer has won the confidence of its customers, while consolidating a new perception of BERALMAR as a complete supplier of the ceramic industry. The near future looks promising, with various new projects about to be started.

Currently, BERALMAR’s Projects Department is composed of 16 professionals, among engineers, drawers and construction supervisors.

On the first week of October the start-up of a solid fuel firing system took place at CERÁMICA DEL REINO in Bailén (Spain), for a daily production of 550 tonnes of hollow brick. The installation, model MICROMATIC, supplies 70% of the energy consumed by the kiln.

This installation adds up to a total of 24 orders of this kind of firing systems received by BERALMAR only in 2006, from 5 different countries.

The interest perceived at BERALMAR for this kind of equipment suggests a steady demand mid term.

BERALMAR is the most experienced supplier of solid fuel firing systems of the market, with installations in more than 100 kilns.

BERALMAR has been chosen to take over the construction of a new brickyard in Algeria.

The future BRIQUETERIE TIMADANINE will be an efficient and rational facility for a daily production of 250 tonnes of hollow brick, which will count with a model FORNTHERMIC tunnel kiln and a dryer of green loading on platforms, model GARBI.

This drying installation provides big savings in automation devices, and it is appropriate for clays of high mechanical resistance and all types of hollow bricks.

The main fuel of the future facility will be natural gas, abundant and cheap in the northern African country.

The start-up of the project is due in September 2007.

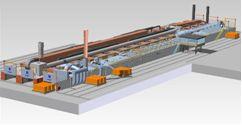

BERALMAR is working on a new project: the design and construction of a new complete plant for CERÁMICAS ALONSO in Ayelo de Rugat (Valencia), Spain, which will add up to other 3 existing plants of this important ceramist group, founded in 1930.

The new installation will be composed of a dryer of green loading on kiln cars, model LLEVANT, of two tunnels, and tunnel kiln model PRESTHERMIC. The brickyard will have an installed capacity of 350 tn/day of partition wall brick (bardo), among other.

The main virtue of this green load dryer lies on the savings on automation devices, while reducing at the same time the maintenance of the plant. Also, the dryer model LLEVANT works automatically at the same production capacity of the kiln at every time.

The main fuel of this installation will be natural gas.

The start-up is expected in spring of 2007.