|

|

| Newsletter 87 - November 2014 |

| Approximate reading time: 5 minutes |

|

|

|

|

- Corporate

-

HISTORY OF BERALMAR, 9/10: 2013-14 – AWARDS AND PRESENT-DAY

|

|

|

With half a century of experience, BERALMAR stands out today as a comprehensive supplier with about 70 professionals in its workforce, offering extensive equipment and engineering project assets for the structural ceramics industry:

|

| |

EQUIPMENT DRYING:

- All types of fans.

- All types of heat-generation equipment for all types of fuels.

- Dryer automatic control. |

|

ENGINEERING PROJECTS DRYERS:

- Rapid.

- Shelf semi-continuous dryers.

- Platform semi-continuous dryers.

- Direct loading on kiln cars.

- Chamber dryer. |

|

| |

|

|

| |

FIRING:

- All types of combustion installations for any type of fuel.

- Automatic kiln control. |

|

KILNS:

- Traditional tunnel kiln.

- Airtight tunnel kiln. |

|

| |

|

|

| |

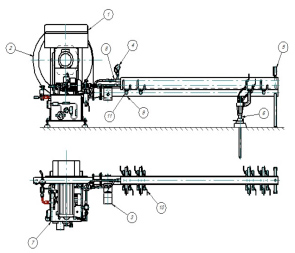

AUTOMATIC EQUIPMENT:

- Cutting.

- Dryer loading and unloading.

- Kiln car setting and dehacking.

- Kiln car movement.

- Packaging. |

|

COMPLETE PLANT PROJECTS |

|

BERALMAR designs its proprietary technology and manufactures its entire range of equipment in its head office in Terrassa. It boasts modern and appealing facilities conveniently located in a well-connected industrial area only 20 minutes from Barcelona. This location is one of the company’s significant assets. At BERALMAR we promote client visits and highly value the fact that we receive customer visits every week.

Although we have grown to become a comprehensive service provider, BERALMAR does not forget its roots and accepts any type of enquiry, large or small, from any market.

Currently, BERALMAR is organised in the following departments:

MANAGEMENT AND ADMINISTRATION

The company is managed by its two shareholders, Cristóbal Caparrós and Ramón Sarió, who are fully and exclusively dedicated to BERALMAR.

The Administration Department features a very streamlined and efficient administrative structure, whereby 90% of our team is geared to providing direct service to our clients.

SALES DEPARTMENT

|

The Sales Department includes the sales managers, a head of logistics and five area coordinators who oversee more than 60 countries aided by a network of local agents with strong ties to the company over a very long period.

In June 2013 BERALMAR received the Internationalisation Award from the Terrassa Chamber of Commerce for, among other things, exporting over 95% of its turnover.

TECHNICAL ENGINEERING OFFICE

This technical office includes the following departments:

- Machinery design and manufacturing department: BERALMAR designs 100% of the machines it manufactures.

- R&D Department: BERALMAR innovates and applies continuous improvement processes to its entire range of equipment.

- Engineering Department: Kiln, dryer and complete plant design. Site management and project implementation monitoring.

AUTOMATIC EQUIPMENT TECHNICAL OFFICE

This department comprises professionals aged from 20 to 40 years old who are experienced in designing high-end automatic equipment for the ceramics industry. It focuses on two very clear ideas:

- The concept of low cost applied to automatic equipment is a preposterous fallacy.

- The use of quality components and the robustness of automatic equipment is the only approach to a cost-effective investment.

ELECTRIC AND SOFTWARE DEPARTMENT

The wiring diagrams and electrical panels of our equipment are designed and built in our facilities.

A team of industrial software professionals develops the custom automatic control equipment for the drying and firing processes, which also allow for real-time after-sales online support.

MANUFACTURING WORKSHOP AND TECHNICAL SERVICE TEAM

All the equipment designed by BERALMAR is assembled in our own workshop, where we also run our quality tests.

BERALMAR has a team of technical service experts, with a solid track record in international deployment, who specialise in the commissioning of machinery and facilities. They also deal with process control and optimisation. The experience of this team is one of the company’s greatest assets.

|

|

|

|

|

|

-

FOURTEENTH PART OF THE TREATISE ON DRYING AND FIRING

In this fourteenth part, you will find chapter 2.8 (continued) of the treatise on firing:

Chapter 2.8: Types of burners (continued).

2.8.2 Burners for liquid fuels.

2.8.3 High velocity burners for gaseous fuels.

We hope it will be of interest to our readers.

|

|

|

|

|

|

-

CONCLUSIONS FROM THE CLAYTECH CONFERENCE (UK)

|

|

| Miquel Moix giving his presentation. |

Last 20 November, BERALMAR took part in the CLAYTECH 2014 conference organised annually by the UK’s INSTITUTE OF MATERIALS, MINERALS AND MINING (IOM3).

Miquel Moix, from BERALMAR, gave a presentation on alternative fuel technologies at the conference in Stafford’s County Showground. Miquel highlighted BERALMAR’s extensive experience with equipment using fuels other than natural gas, such as petroleum coke, coal, biomass, biogas, synthesis gas and recycled oil.

Download BERALMAR’s presentation at the CLAYTECH conference here.

|

|

|

|

|

|

-

BERALMAR AT THE “REF” CONFERENCE IN KIEV

|

| BERALMAR’s representative, Oleg Polchiy (third from the left), during the discussion. |

The sixth “REF” conference on energy efficiency and energy savings took place last 14 and 15 October in Kiev (Ukraine).

The aim of the conference was to discuss and present efficient solutions for use of fuels other than natural gas, both in industrial/agricultural and domestic applications.

BERALMAR made a presentation at the conference as an innovative manufacturer of machinery fueled by biomass, biogas and synthesis gas. Oleg Polchiy, BERALMAR’s representative, shared with the audience BERALMAR’s experience in industrial applications — especially in the ceramics industry, but also in agriculture — and took part in a general discussion.

We trust that BERALMAR’s contribution to the conference proved beneficial to the public and organisers.

|

|

|

|

|

|

|

The ECTS group, which includes key European ceramics industry suppliers, held its second biennial meeting last 14 November in the German city of Krumbach (Bavaria), at the HANS LINGL GmbH head office. As is customary, the lead-up to the meeting included a lively dinner at the Klosterbräuhaus beer house the night before.

The group has continued accepting new members in recent years, so the meeting at Krumbach has been one of the largest.

One of the decisions taken during the meeting was to organise a joint symposium on ceramics technology. More details will be published shortly in our Newsletter.

We wish to thank HANS LINGL GmbH for organising the event and for their hospitality. The group’s next meeting is scheduled for 22 May at the CERATEC head office in Ploegsteert (Belgium).

|

|

|

|

|

|

-

THE BERALMAR NEWSLETTER, NOW ALSO IN GERMAN

|

| Countries where German is spoken. |

|

| Unofficial flag of the German language Sprachraum (geographical linguistic area). |

BERALMAR’s website has been available in German for many years. And now, beginning with the November issue, German readers will also be able to read the BERALMAR newsletter in their own language.

German, as everyone knows, is spoken by 100 million people. It is the leading language in Europe in number of native speakers and ranks second as the most-learned foreign language in Europe. It is the official language of four European states and four other states (official or regional language), and it enjoys a minority presence in several central European countries.

Including German, the BERALMAR Newsletter is now published in 12 languages.

We hope that the German-language version of our Newsletter will help our German readership see an even clearer picture of the BERALMAR world.

|

|

|

|

|

|

www.beralmar.com | Change language | Unsubscribe | Disclaimer

Beralmar Tecnologic, S.A. | Avda. del Vallès, 304 | E-08227 Terrassa (Barcelona) | T. +34 937 312 200 | info@beralmar.com

|