|

|

| Newsletter 60 - March 2012 |

| Approximate Reading Time: 5 minutes |

|

|

|

|

- Corporate

- BERALMAR AT INDIAN CERAMICS 2012

BERALMAR participated again in this year's edition of the INDIAN CERAMICS fair held from March 20-22 in Ahmedabad, the capital of the state of Gujarat.

BERALMAR values very positively its renewed presence at the leading trade fair for the Indian ceramics industry, which has undoubtedly served to bring together the technologies required for the Indian market and the ideas proposed by BERALMAR.

BERALMAR has several solutions for the Indian ceramics industry. Some with an immediate application, such as GQS solid fuel firing equipment for Hoffmann and BTK kilns, which would provide energy efficiency and improvements in the quality of firing, and others more for the short to medium term, such as the semi-automated factory model made up of a BASICTHERM tunnel kiln and model a TRAMUNTANA dryer, specially designed for the Indian market and characterised by its local supply, the exclusive use of solid fuels and production of around 150-200 tonnes/day, which represent a very modest investment and a quick return.

BERALMAR is determined to play an important role in the modernisation of the Indian ceramics industry and we can therefore say that we will almost certainly be back for the 2013 edition.

Prior to its participation in the fair, BERALMAR gave a presentation on its proposals to modernise the Indian ceramics industry at the symposium organised by TERI and ECTS (European Ceramic Technology Suppliers) in Bangalore.

|

|

|

|

|

- News and Accomplishments

-

NEW PROJECT IN BOLIVIA

|

|

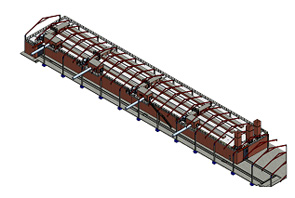

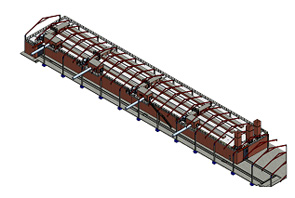

| Close-up of the semi-continuous dryer |

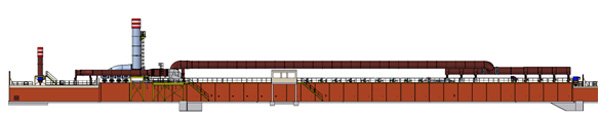

BERALMAR is working on an important new project. This is the provision of a tunnel kiln and dryer for the new production line at CERÁMICA DEL ESTE in Santa Cruz de la Sierra (Bolivia).

The new facility is expected to reach a production of 600 tonnes/day of hollow bricks and consists of a 127 metre-long FORNTHERMIC tunnel, including pre-kiln, with an internal width of 4.5 metres and a MESTRAL semi-continuous dryer with 6 kiln car lanes. Both the kiln and the dryer will be operated by MICROBER and MICROSEC automatic control equipment respectively.

The main fuel used in this new production line will be natural gas, which is abundant in the Andean country.

We would like to take the opportunity to thank CERÁMICA DEL ESTE for the trust they have deposited in BERALMAR.

|

|

|

|

|

|

- NEW ORDER FOR A SOLID FUEL FIRING FACILITY IN HUNGARY

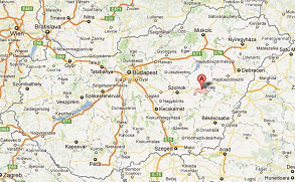

BERALMAR has just received a new order for a solid fuel firing facility in Hungary. This is a MICROMATIC facility for the KUNSÁGI TÉGLAIPARI ceramics plant in Kisújszállás, in the eastern part of the country.

The fuel used is micronised petroleum coke, which will arrive at the factory with a maximum particle size of 100 µm and less than 1% moisture and will be stored in a silo for eventual transportation to the firing area and dosification to maintain the current firing curve, all through the pneumatic transport of fuel and centralised and automated control of the entire process.

The MICROMATIC facility will replace at least 80% of current consumption of the kiln’s natural gas and will achieve significant savings in energy bills for the factory, with a clear return on investment of less than one year.

It is hoped that these and other similar facilities will continue to proliferate in Central Europe, given the continued increases in natural gas prices.

|

|

|

|

|

|

www.beralmar.com | Change language | Unsubscribe | Disclaimer

Beralmar Tecnologic, S.A. | Avda. del Vallès, 304 | E-08227 Terrassa (Barcelona) | T. +34 937 312 200 | info@beralmar.com

|