|

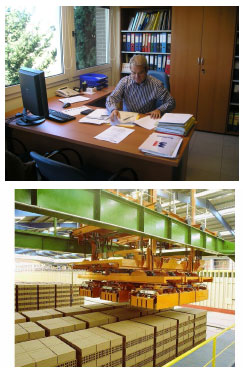

INTERVIEW WITH CAYETANO JIMÉNEZ, HEAD OF BERALMAR'S AUTOMATION DEPARTMENT

In 2009, BERALMAR opened a new Automation Department which entails a huge qualitative leap as supplier to the ceramics industry and as a result we thought it appropriate to carrying out the following interview with its head, Cayetano Jiménez.

NEWSLETTER BERALMAR: Our readers would like to know who Cayetano Jiménez is and what experience he has in our sector.

CAYETANO JIMÉNEZ: Well, since starting in 1969 as a planner at SEVECO, manufacturer of automation systems linked to eth AGEMAC group, until now, I have accumulated 40 years of experience in the world of automation systems for the ceramics industry. I was Director of Projects at SEVECO from 1974 to 1990, a role I combined with that of Director of the Technical Office at AGEMAC from 1990 to 1998 when the AGEMAC group collapsed. Since then I have been a part of, always as Technical Director, the INGICER and PRC projects until landing at BERALMAR this year.

NB: I understand that you have managed complete line automation projects in countless countries.

CJ: Yes I have. I've been lucky enough, through the organsations in which I've worked, to carry out projects in Western Europe, the former Soviet Union, China, Noth America, Arab countries, Southeast Asia, Latin America, South Africa, Australia...

NB: Wow, wouldn't it have been quicker just to say “the whole world”?

CJ: Well, the world is very big, but it's true that I must have managed projects in over thirty countries.

NB: What does it mean for a professional with your experience to join a company such as BERALMAR?

CJ: It's very satisfying because although BERALMAR has never manufactured automation systems, it has always been a pioneering, innovative manufacturer in everything it has done. It is a top calss company which will allow me to continue my career as head of an automation systems design and manufacturing team. Moreover I believe this has been a natural step for BERALMAR as a supplier. With its experience in the fields of drying and firing, it was natural to enter the field of automation.

NB: What can you tell us with regards to your team?

CJ: It's a team that combines youth with experience. My collaborators have between 10 and 22 years of experience designing and manufacturing automation systems and as a result they have acquired a certain maturity in this field while still having a long way to go.

NB: The arrival of your team at BERALMAR signifies an important increase in know-how. What are we talking about? What distingusihes BERALMAR's new automation systems offering?

CJ: On the one hand I would say that it is now a complete offering. We have experience in any solution for any part type: cutters, loading and unloading of any type of dryer, different truck stacking and destacking solutions, packaging, robotics applications, transport etc. You can say that there is no need which we can't cover.

NB: Now you just need the orders to arrive

CJ: Well, BERALMAR already sold automation systems before we got on board, as part of their supply of complete plants. The difference is that now with the new Automation Department its propietary technology designed and manufactured by BERALMAR like the rest of the drying and firing equipment. In this sense we have joined a company with a very active organisation which was already immersed in different projects and after a necessary integration and coordination period with the other departments we are lucky enough to already be busy with certain projects.

NB: Long may it last!

CJ: Touch wood. It must be said that our integration has been easy for two reasons. On the one hand I already knew Artur Massaguer (BERALMAR's Technical Director) very well from my time at AGEMAC, as well as other professionals in the company. In addition, we have encountered an extraordinary working environment at BERALMAR and we have been made to feel very welcome both by Management and by our new colleagues in the other departments. In this sense I would like to take advantage of the interview to say thanks publicly on behalf of all my team.

|