|

Approximate reading time: 5 minutes

Ceramics Industry

MEETING IN MUNICH OF THE LEADING EUROPEAN SUPPLIERS

On the occasion of the CERAMITEC 2009 trade fair, the half-yearly meeting of the ECTS (European Ceramic Technology Suppliers) Group, which is made up of the leading European suppliers for the ceramics industry, was held in Munich on the 19th of October.

The number of companies in the group grows each year and as such the group welcomed 3 new members: SACMI, BEDESCHI and TECNOFILIERE.

Topics discussed during the meeting included the situation of certain markets, common sales efforts and the formation of work groups.

The next meeting will take place in May 2010 in Osnabrück (Germany) and will be hosted by group members ELSTER, VHV and BURTON.

800 YEARS OF CERMAMICS CONSTRUCTION IN POLAND

The 800 year anniversary since the first documented use of ceramics as a construction material in Poland took place in Warsaw last Wednesday 7th October.

During this very formal event, over a hundered important poeple within the current Polish cermaics industry were awarded prizes.

BERALMAR wanted to be present and take this opportunity to greet friends and acquaintances from the industry.

|

Corporate

CERAMITEC 2009

The CERAMITEC 2009 trade fair was held in Munich between the 20th and 23rd October and was very positive for BERALMAR.

For one thing, this edition of CERAMITEC was the perfect occasion for BERALMAR to present its new offering of automation systems and inform vsitors about them accordingly.

According to organisation officials, about 15,000 accredited professionals visited the event, a number in line with expectations for a leading global exhibition but modest compared with the 22,000 visitors during the 2006 edition.

This decrease in the number of visitors, a reflection of the difficulties faced by the construction industry in many countries, was not noted at the BERALMAR stand which attended to representatives from almost 150 ceramics facilities in 34 countries. If we add to this the quality of the enquiries we can confirm that for BERALMAR, CERAMITEC 2009 was a great success.

BERALMAR's participation at CERAMITEC 2009 was rounded off with the presentation “New Energies for the Ceramic Industry” given by BERALMAR's head of R&D, Santi Amposta.

We would like to take this opportunity to thank all our visitors for their efforts and kindness for coming to see us and Messe München for the superb organisation, with the hope of meeting again in Munich in 2012.

|

News and Accomplishments

MODERNISATION OF THE SAVERDUN TERRE CUITE CERAMICS FACILITY

BERALMAR has carried out an important modernisation project at the SAVERDUN TERRE CUITE ceramics facility in Saverdun (France). SAVERDUN TERRE CUITE is a manufacturer of over one hundred formats and specialises in high quality ceramic finishes.

The projects objectives were 1) to increase production, 2) to optimise quality and 3) to automate the manufacturing processes.

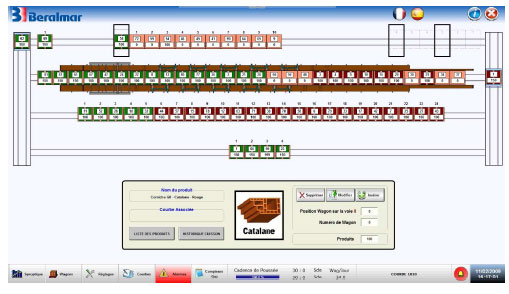

To achieve these onjectives, new gas combustion equipment and kiln ventilation were installed. A new air recovery system for the dryer with a mixing chamber and gas burner was also installed. But the most interesting changes were the installation of a new automatic control system for the kiln and dryer and the new transport system with "car tracking" for the automated tracking of each wagon and management of the firing curve depending on the load, which is a very important aspect considering the endless list of formats manufactured in this facility.

It should be noted that the automatic kiln management control system incorporates an alarm and incident management system which allows the total absence of personnel in the facility over the whole weekend, with the help of a warning system using text messages and e-mails.

NEW SOLID-FUEL FIRING INSTALLATION IN SERBIA

BERALMAR has just commissioned a new PROMATIC model solid fuel firing installation for the MLADOST group, in this case in the MLADOST-RAD facility in Vlasotince (Serbia).

The new firing facility, designed to produce 500 tonnes/day of ceramic blocks, operates using petroleum coke, which substitutes approximately 65% of the kiln's natural gas consumption, resulting in energy savings.

This is the second PROMATIC system which BERALMAR has installed for the MLADOST group after the unit also installed in the MLADOST-TMP plant. We appreciate the continued confidence deposited in BERALMAR.

|