|

Approximate reading time: 5 minutes

Ceramics Industry

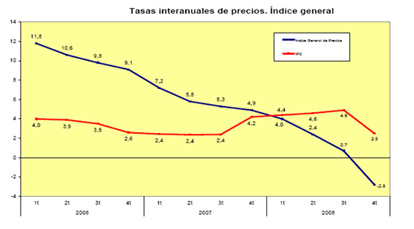

Housing prices drop in Spain

For the first time since 1993, housing prices in Spain have suffered a setback in the last quarter of 2008. This graph shows the history of housing prices (blue line) against inflation (red line), as reported by the Spanish Association of Brick and Tile Manufacturers (HISPALYT).

In the last quarter of 2008, house prices continued to rise in nine provinces, especially in Seville, Cadiz and Pamplona. The most dramatic declines were in the central provinces, with falls of up to 10% in Guadalajara, Cuenca and Madrid.

The average price of housing in Spain at the end of 2008 was €2,022 /m2 for new housing and €2,007/m2 for used housing, with the following ranking by city: Getxo, €3,861/m2; San Sebastián, €3,786/m2; Sant Cugat del Vallès, €3,711/m2; Barcelona, €3,681/m2; Esplugues de Llobregat, €3,640.50/m2 and Madrid, €3,568/m2.

|

News and Accomplishments

Improvements in PÁPATESZÉRI TÉGLAIPARI Kft.

BERALMAR is undertaking a number of improvements in the dryer at the PÁPATESZÉRI kiln in Pápa (Hungary). This dryer was built by BERALMAR in 2002, and since the installation of the new tunnel kiln in 2008, also by BERALMAR, the dryer has become the bottleneck of the factory.

On the one hand, more recirculation fans are being installed to increase the dryer’s production capacity by 50%. A MICROSEC automatic dryer management system is also being installed, which will allow greater control of the process.

The PÁPATESZÉRI kiln continues to demonstrate the ongoing trust in BERALMAR equipment and services. .

|

|

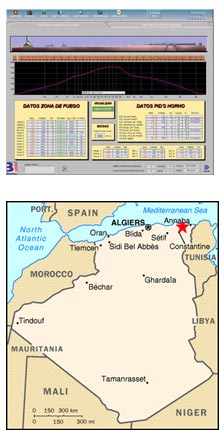

Expansion and modernisation of BRIQUETERIE EL RYAD

BERALMAR is carrying out some expansion work on the kiln and dryer of the BRIQUETERIE EL RYAD in Annaba (Algeria).

The semi-continuous dryer consists of two drying lines, to which BERALMAR is adding a third. Besides the construction of a new drying line, a MICROSEC automatic management control is being installed. The goal, in addition to increasing the capacity of the plant, is to correct certain problems in the process.

The production capacity of the tunnel kiln itself is being boosted by adding new high-speed gas jets, an air pre-heating system, and automation of the kiln process using the MICROBER management program. These changes are expected to increase production by 15%.

Enhancing existing facilities is a BERALMAR area of expertise, because this type of activity combines engineering knowledge and the implementation of all types of drying and firing equipment manufactured by BERALMAR.

|