|

Reading time approximately: 5 minutes

Holidays

HAPPY CHRISTMAS!

We couldn’t start this month’s newsletter without wishing the entire ceramic family a Merry Christmas and a Prosperous New Year!

The BERALMAR offices will be closed over the festive period from December 22nd to January 6th inclusive.

We hope that you all benefit from a well-earned rest and pleasant festivities and wish you all the best both personally and professionally.

Happy holidays! |

Corporate

2008, THE YEAR FOR TRADE FAIRS

The forthcoming year will be an intense one for BERALMAR in terms of trade fairs. Visitors can find our stand at CEVISAMA (Valencia, February 5th-9th), MOSBUILD (Moscow, April 1st-4th), and BATIMATEC (Algeria, April 28th-30th). BERALMAR will also take part in a symposium organised by the ECTS (European Ceramic Technology Suppliers) at the INDIAN CERAMICS trade fair in Mumbai (India), where we will give a presentation on firing equipment.

We hope to see you there!

|

News and Achievements

NEW SOLID FIRING INSTALLATION IN CHILE

The Chilean ceramic company, INDUSTRIAS PRINCESA, which already has a BERALMAR solid firing installation, has once more placed their trust in our equipment with an order for a second kiln.

The firing installation, which will be manufactured by BERALMAR, will comprise a MICROMATIC SYSTEM and grinding unit, composed of a BERALMAR-built integral mill, and will supply approximately 70% of the necessary fuel (in this case coal) to produce 350 tonnes per day of hollow bricks.

In addition, BERALMAR will install a new MICROBER model automatic control system for the same kiln.

Including the orders received in recent months, the number of solid firing installations completed by BERALMAR in Europe, America, Asia and Africa over the last 23 years is approaching 200 units, confirming BERALMAR as a great specialist within the sector for this type of installation.

|

|

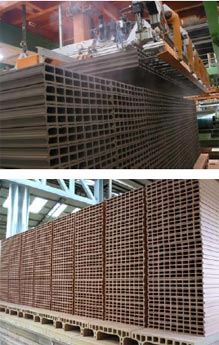

PRODUCTON OF “CARROBRICKS” IN GREEN LOAD DRYER

CERÁMICAS DE MIRA (Cuenca, Spain) boasts a factory which was designed by BERALMAR and which became operational in summer 2006. This production unit comprises a LLEVANT model green load dryer and a hermetic PRESTHERMIC model tunnel kiln.

One of the characteristics of this type of dryer is the flexibility of production, both in terms of the ease with which production can be increased and reduced and the variety of pieces that can be manufactured. This flexibility of production was more than proven when CERÁMICAS DE MIRA started production of 300 tonnes/day of 500 x 700 x 70 mm Carrobricks, an operation which was a complete success.

It is remarkable that over the last 18 months, since this installation became operational, the specific consumptions recorded for drying and firing have varied at all times between 280 and 300 Kcal per kilo of fired material; a spectacularly low consumption, which arises from the union of a hermetic kiln and a green load dryer, which is fuelled almost exclusively by recovered heat from the kiln. It is the only large-scale production unit with a green load dryer in Spain.

|

|

|

In this edition:

Holidays |

|

|

|

Corporate |

|

|

|

News and Achievements |

|

|

|

|

|

| |

|

|

|