|

|

| Newsletter 81 - April 2014 |

| Approximate reading time: 5 minutes |

|

|

|

|

- Corporate

-

HISTORY OF BERALMAR, 3/10: 1986-90 – SPECIALISATION IN PROCESS IMPROVEMENTS

|

|

After some particularly critical years, the second half of the eighties was a period of great growth and commercial success, with a high volume of fuel oil gasifier and gas appliance sales and the replacement of petroleum coke equipment with these fuels.

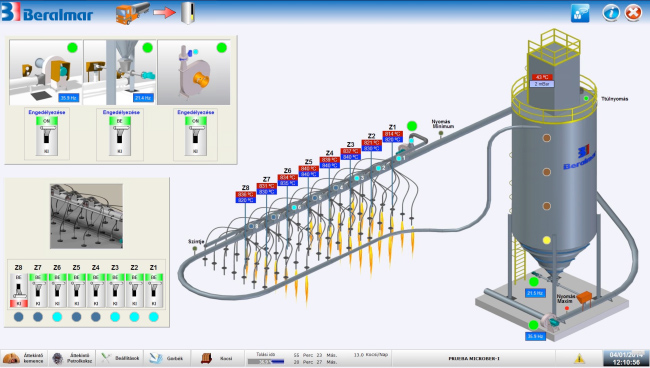

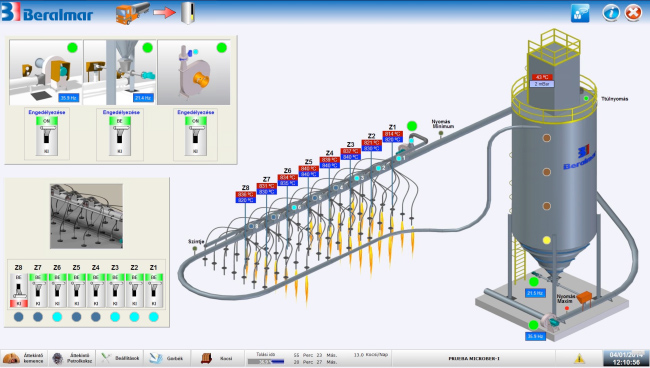

Another outstanding fact is that this stage saw the company start to supply automatic control equipment for drying (MICROSEC) and firing (MICROBER) processes, facilitated by the advances in computing equipment of the age.

At the same time, the foundations were laid during this period for a specialisation that would become one of the company’s strengths: specialisation in drying and firing process improvements. Due, on the one hand, to this frenetic equipment supply activity and, on the other, to the beginning of automatic process control equipment supply, the company’s specialists made a great qualitative leap in their understanding of kiln and dryer control. This specialisation was an added value the market appreciated. When customers bought BERALMAR equipment they knew the purchase would be accompanied by a knowledge of the craft that translated to good advice as regards the equipment needed and improvement of energy consumption and production quantity and quality parameters.

At the end of the eighties the company had 17 employees.

|

|

|

|

|

|

-

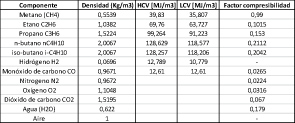

EIGHTH PART OF THE TREATISE ON DRYING AND FIRING

In this eighth part, you will find chapter 2.7 of the treatise on firing:

- Chapter 2.7: Fuels and combustion

- 2.7.1 Classification of Fuels.

- 2.7.2 Heat from Combustion.

- 2.7.3 Complete Combustion.

- 2.7.4 Determining the Amount of Air Needed.

We hope it will be of interest to our readers.

|

|

|

|

|

|

-

CONCLUSIONS FROM THE MOSBUILD FAIR 2014

As we announced, BERALMAR took part in the 2014 MOSBUILD Fair, held between 1 and 4 April in Moscow (Russian). This was a highly satisfactory edition.

This was the best rated of recent years in terms of the number and quality of the visits to our stand and it was a wonderful opportunity to move some projects forward that we hope come to fruition in time.

BERALMAR is already busy with several projects in the Russian market.

|

|

|

|

|

|

-

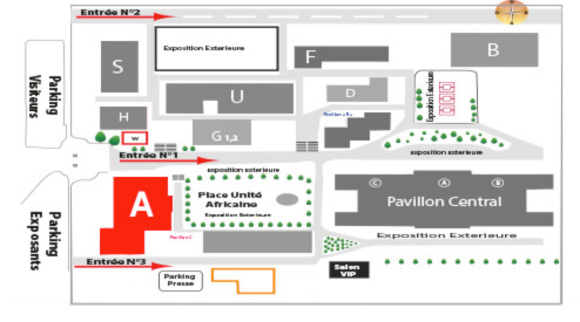

BERALMAR AT THE 2014 BATIMATEC FAIR

This year is probably the most intensive in BERALMAR’s history in terms in participation in fairs and, logically, we could not miss BATIMATEC, the reference construction show in Algeria where BERALMAR has had its own stand for over 15 years.

BERALMAR will also be offering a presentation on production lines on day five, with dryers with direct loading onto kiln cars and their advantages. BERALMAR happens to have supplied a line of this type to BRIQUETERIE EL RYM in Annaba, which went into service at the end of 2012 to produce around 700 tonnes/day of blocks.

This year’s edition will take place from 4 to 8 May and visitors will be able to find BERALMAR’s stand at location AS-04 in pavilion A on the show ground in the Algerian capital.

We look forward to seeing you there!

|

|

|

|

|

|

|

-

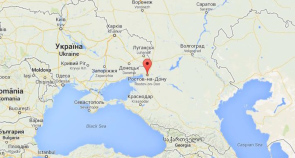

BERALMAR AT THE 2014 KERAMTEX CONFERENCE4

BERALMAR will be present again this year at KERAMTEX, the Russian ceramic industry conference to be held on 28 and 29 May in the city of Rostov-on-Don.

Rostov is a city on the Black Sea coast with over one million inhabitants and a large port. It is commonly known as the gateway to the Caucasus.

BERALMAR will take the chance to offer a presentation on “Technologies for clinker brick format manufacturing in Russia”, given by Yuriy Zinyak and Enric Simón, which we believe will be of interest to attendees.

|

|

|

|

|

|

- News and Accomplishments

-

SECOND MICROMATIC INSTALLATION IN HUNGARY

BERALMAR has just successfully commissioned the second MICROMATIC installation in Hungary, specifically in the PÁPATESZÉRI TÉGLAIPARI ceramic plant in Pápateszér, midway between Budapest and Vienna or Bratislava.

This facility was dimensioned for production of up to 250 tonnes/day with natural gas pre-heating.

This is the second MICROMATIC system BERALMAR has installed in Hungary, where petroleum coke specially prepared for the ceramic industry and supplied by tanker has been available since last year. This fuel has the following characteristics:

Calorific value 8,400 kcal/kg

Moisture < 1%

Particle size < 100 µm

Ash < 1%

With the current fuel prices in Hungary, the replacement of a significant portion of natural gas with this fuel makes it possible to achieve cost savings that are now almost essential.

We would like to record here our thanks to the Valdinger family and their team for the trust placed in BERALMAR.

|

|

|

|

|

|

|

www.beralmar.com | Change language | Unsubscribe | Disclaimer

Beralmar Tecnologic, S.A. | Avda. del Vallès, 304 | E-08227 Terrassa (Barcelona) | T. +34 937 312 200 | info@beralmar.com

|