|

Approximate reading time: 5 minutes

CORPORATE

Interview with Artur Massaguer, technical director of Beralmar

Artur Massaguer has been Technical Director at BERALMAR since 1998. From the very beginning, his mission has been to create a new Projects Department that would help BERALMAR increase its offer with a complete range of kilns and dryers. Nine years after establishing this Department, Artur shares his thoughts with us.

BERALMAR NEWSLETTER: What is your evaluation of the Projects Department’s first nine years?

ARTUR MASSAGUER: Taking into account past and current projects, we are talking about more than 20 kilns and more than 20 dryers in just nine years. Considering that we started from zero, my general evaluation is absolutely positive. It must be said that around 70% of our task has taken place outside the domestic market. Another aspect to be considered is the human team that has evolved during these years. The team consists of professionals with great experience in the industry and young professionals that guarantee the future of the Department. After nine years, we have a Projects Department with a respectable track record and a consolidated professional team.

BN: What distinguishes BERALMAR’s project offering? What added value does BERALMAR give brickmakers for their projects?

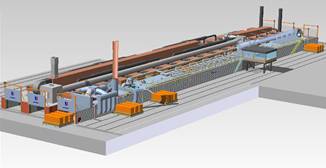

AM: When BERALMAR initiated its ceramic engineering activities, it combined the existing experience related to equipments for firing and drying with project design. This made us rethink the kiln completely and drove us to develop the Fornthermic and Presthermic models, which incorporate elements based on previous BERALMAR knowledge. Another example of this is the Llevant model dryer, which features air circuit technology and other technological improvements in relation to what was available on the market. It is worth noting that BERALMAR is one of the few suppliers with a complete offer: engineering, equipments, control systems, etc. An overall characteristic of our projects is that from the very moment they are conceived, we have precise knowledge of the equipment at our disposal. BERALMAR also offers a wide range of dryers. This experience in the construction of various types of dryers allows us to propose the most adequate type of dryer for each case, based on to the pieces to be manufactured, the type of clay, etc. This sets us apart from suppliers that are familiar with just one or two types of dryers and may be forced at times to propose them even for inadequate applications. The same applies to the equipment that we integrate in our projects. Since we manufacture firing and drying equipment for all types of fuels (solid, liquid and gas), we are poised to offer the very best choice of equipment, and we are able to adapt our projects on the basis of fuel choice.

BN: What is the Projects Department’s potential?

AM: The BERALMAR team has grown from 25 employees ten years ago to a workforce of 60 strong today. This personnel increase is due to the creation of the Projects Department, the growth of the entire Technical Office and the increase of start-up technicians. We have carried out many projects in a short amount of time, the degree of customer satisfaction is remarkably high and we count with a solid Projects Department that continues to grow steadily. We stand on a strong foundation to become a benchmark engineering firm, and therefore our potential is very high. We still have a long way to go!

|