GERIM rapid cooling

Rapid cooling is used to bring down firing temperature quickly to around 650º C, a temperature that is close to yet not exceeding quartz transformation temperature, to ensure no problems arise in the critical zone.

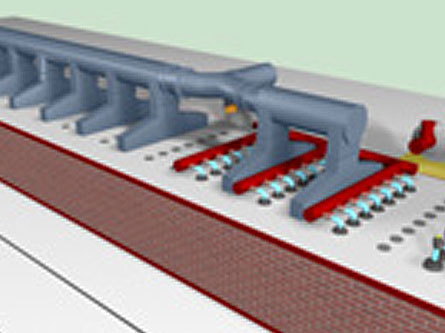

It is best to extend cooling so that the material package has time to homogenise and equalise temperatures inside and outside the package. It is also best to intersperse high-temperature air suction with cooling air injections. In this way Beralmar recommends using a rapid cooling injection line and a high temperature recovery line, where suction will help injection to be more consistent with the package temperature.

A major enhancement to existing rapid cooling systems is that pulses are used throughout the line. This helps to provide additional turbulence designed to aid temperature equalisation.