|

|

| Newsletter 92 - April 2015 |

| Approximate reading time: 5 minutes |

|

|

|

|

- Corporate

-

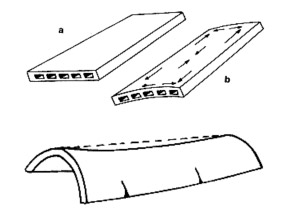

NINETEENTH PART OF THE TREATISE ON DRYING AND FIRING

This nineteenth part covers chapters 1.14 and 1.15 pertaining to the treatise on drying:

Chapter 1.14: Energy saving guidelines for a dryer

Chapter 1.15: Drying defects, causes and remedies.

We hope it will be of interest to our readers.

|

|

|

|

|

|

-

CONCLUSIONS FROM THE 2015 MOSBUILD FAIR

|

|

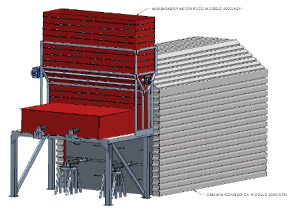

| Image of the KCM-2 ceramic plant in Kansk, Siberia. |

BERALMAR took part in the MOSBUILD (Russia) fair between the 14th and 17th of April.

This edition has been marked by a noticeable drop in visitors, since investments have been hampered by the impact of the ruble exchange rate.

Despite the overall decline in visitors compared to previous editions, the BERALMAR stand received many visitors interested in learning more about the KCM-2 ceramic plant supplied by BERALMAR last year near Kansk (Siberia). In fact, this new ceramic plant boasts two unusual features in Russia: the use of coal as the only heat source, and especially the type of dryer featuring direct stacking onto kiln cars.

This year BERALMAR expects to commission a new factory in Russia which also features an unusual element for the country. Stay tuned for newsletter updates.

|

|

|

|

|

|

-

BERALMAR AT THE 2015 BATIMATEC FAIR

Continuing its yearly tradition, BERALMAR will participate at the BATIMATEC fair in Algiers (Algeria) over the coming 3rd to 7th of May.

2015 is an important year for BERALMAR in Algeria, as the company is set to commission two new factories:

- BRIQUETERIE AMRAOUA, which we reported on last January.

- BRIQUETERIE TIMADANINE 2, which we will report on soon.

Visitors will find the BERALMAR delegation at the S-13 stand in Hall A.

We look forward to seeing you there!

|

|

|

|

|

|

|

| Miquel Moix during his speech at the symposium. |

On April 24th a symposium on ceramic technology took place in the city of Izmir (Turkey).

The symposium, organized by the ECTS and one of its member companies, AR-SAN MAKINA, had the support of TUKDER, the Turkish Ceramist Association.

The symposium featured presentations from 17 European suppliers who are members of the ECTS, including BERALMAR, who gave a presentation entitled "Proposals for the Turkish Ceramics Industry" by Miquel Moix. He focused on switching over from Hoffmann kilns to tunnel kilns (keeping coal as the main fuel) as a solution for drastically reducing rising labor costs and addressing labour shortages resulting from the Turkish economy’s strong and sustained growth.

We take this opportunity to acknowledge the efforts made by ECTS and AR-SAN MAKINA, in collaboration with the Turkish Ceramist Association, to make the symposium a great success, attended by delegates from more than 40 ceramic plants nationwide.

|

|

|

|

|

|

|

- News and Accomplishments

-

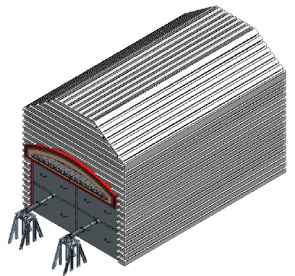

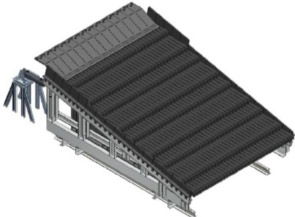

NEW SOLIDS COMBUSTION CHAMBER WITH MOVING GRATE

BERALMAR has great expertise in the field of heat generation using dryers. Proof of this are the more than 500 generators supplied throughout the company’s history, and the wide array of solutions, ranging from various types of direct flame combustion chambers to heat exchangers for both liquid and solid fuels.

Due to growing interest in the use of solid fuels in the drying process, BERALMAR has expanded its line of direct flame combustion chambers for solid fuels with the newly-designed CGM?? model chamber.

BERALMAR’s objective when developing this new combustion chamber has been to offer a solution which is as simple as possible from an operational standpoint. The company has chosen to equip the new CGM chamber with a moving grate system, which allows:

- Automatic and continuous ash disposal, thus eliminating one of the tasks associated with the use of other types of solid fuel combustion chambers.

- Enhanced combustion efficiency, as compared to other models, brought about in fact by the constant evacuation of ashes from the grate, which allows constant use of its full combustion surface.

The solid fuels accepted by the CGM model combustion chamber are as follows:

- All kinds of mineral and vegetable coals.

- All kinds of biomass.

BERALMAR is working on developing more solutions in the field of heat generation. Stay tuned for updates soon.

|

|

|

|

|

|

www.beralmar.com | Change language | Unsubscribe | Disclaimer

Beralmar Tecnologic, S.A. | Avda. del Vallès, 304 | E-08227 Terrassa (Barcelona) | T. +34 937 312 200 | info@beralmar.com

|